What is Channelled Insole Goodyear Welt?

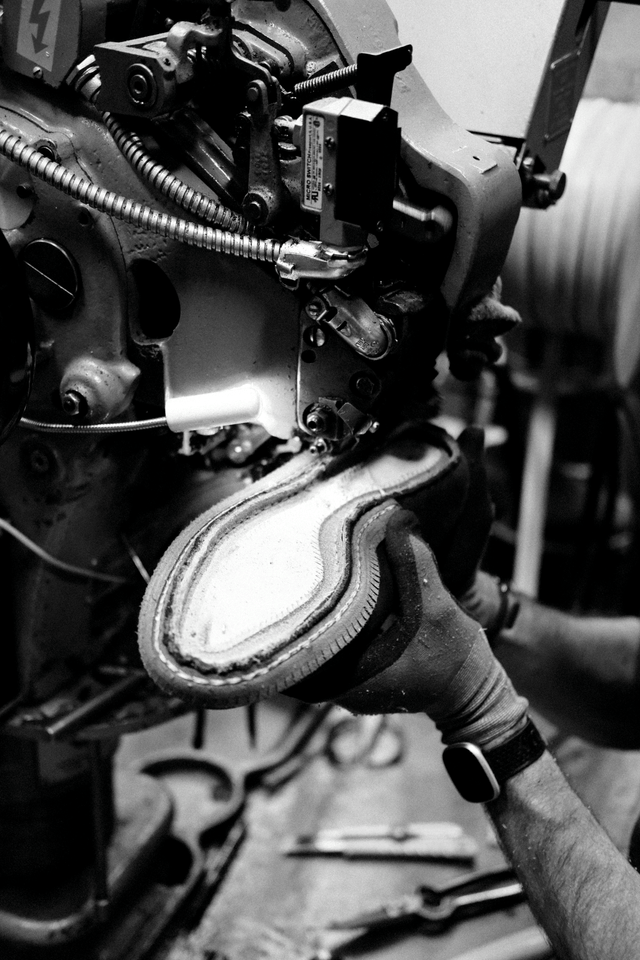

Goodyear Welt is one of the traditional methods of constructing shoes that dates back to the 1860s. The process is broken down into two components: the leather upper of the shoe, and a shoe last with an insole attached. A shoemaker then 'lasts' or forms the upper around the last by hand with pliers, or with machine assistance, and temporarily attaches the leather shoe upper to a holdfast or rib with some type of glue, staple, or nail. The process is just to temporarily hold the last shoe in place while the operator machine stitches the welt on the exterior of the shoe, which stitches through the leather shoe upper, holdfast or rib. This allows the entire shoe to be attached together with the welt, which is a thin strip of leather that the outsole gets attached to.

The simplicity of this construction is that it allows for resoling and recrafting, and no external holes are made through to the inside while attaching the shoe together. This allows for an almost watertight construction compared to comparable methods.

Traditionally, this type of construction was made using the same principles as a hand-welted shoe using a channeled leather insole, in which the foot sits directly upon the insole, to which the welt and the entire shoe are attached. What this meant was that the welt was sewn directly into a thick solid leather insole, allowing for maximum comfort and longevity for your feet.

Today, 99% of all Goodyear Welted footwear is created with a lighter-weight insole, which allows for easier break-in along with a glued on rib, known as gemming, which mimics the original concept of an all-leather holdfast or rib, channeled from the heavier leather insole.

The advantage of the modern Goodyear shoe is that it is much faster to produce more, with a lower failure rate. It also doesn't require the best materials to allow channeling to happen, and allows for easier break-in due to lighter materials internally.

The benefit of a Channeled Insole Goodyear Welted shoe is that the entire shoe is attached to the insole, which flexes with your total bodyweight with each step. This allows the shoe to bend, mold, and perform completely differently from the modern version with a gemmed rib. The thickness difference of the insole of Channeled Welt is about 2.5x heavier than gemmed. This is due to the holdfast or rib that needs to be channeled or carved from a piece of leather. With a glued-on rib, the standard thickness would be around 2.5mm with a solid leather insole.

With wear, the difference between these two methods will become more apparent in the actual structural support of the shoe internally. The popularity of vintage garments and footwear is a classic example of this.

The preservation of a craft in modern society is something that does not happen enough. We have been fortunate enough through Edwin Viberg's original implementation of Channeled Insole Goodyear Welted footwear to understand the importance and value of these methods that no longer exist.